Rope Brake

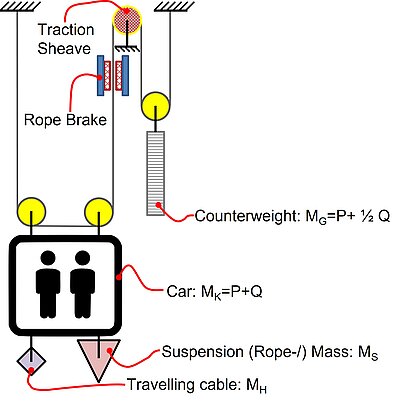

The rope brake is an additional safety component in a lift, that brakes its suspension ropes.

The brake process will either be initiated by the lift control or by the tripping of the overspeed governor.

The rope brake works with compressed air and presses a movable plate against a stationary one.

The suspension ropes run in between both plates and are braked due to the friction force that both plates produce once they are pressed together.

Whether such a rope brake can be used in a particular lift application depends strongly on the lift design.

Therefore it is the lift manufacturer's duty to finally decide, whether or not a rope brake is suitable for the lift in question.

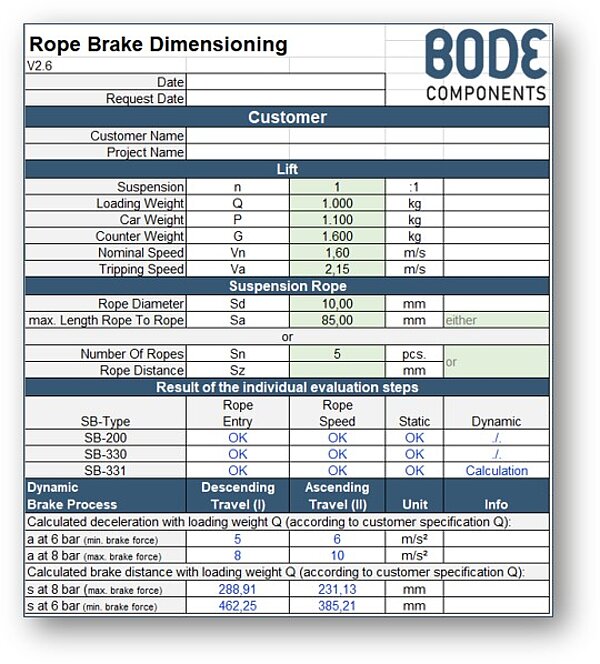

Rope Brake Calculation

To facilitate this decision, BODE offers a specific calculation.

This is only a pure theoretical approximation of the application to support the decision making process.

The calculation tool requires some application specific parameters, that can be provided from the lift manufacturer via our questionnaire.

We will certainly be happy to provide the results of our calculations in a PDF-file.

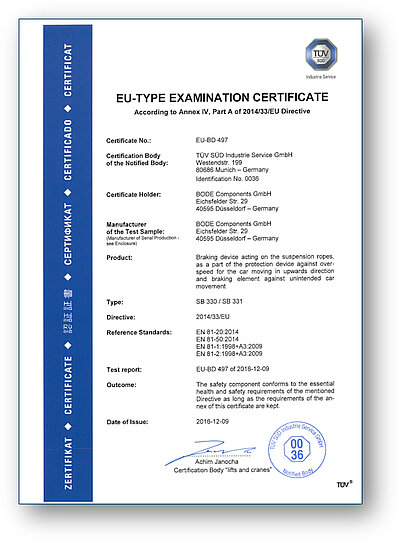

Certification requirementes

Since the rope brake is a safety component, it has undergone an extra type examination procedure by a notified body (TÜV Süd).

To ensure safe operation, various requirements have to be fulfilled. Those are described in the type examination document, that can be downloaded here.

The requirements can be summarised in short as follows:

- regular self-test once in 24 hours

- minimum air pressure of 6 bar

- compressed air volume to allow for at least 3 brake operations

without re-filling of the pressure reservoir

Thanks to our electronic brake control RBC 14, these requirements can be easily met.

Our all-in-one package offers all necessary accessories, incl. compressor, hoses, water separator and also the RBC 14.